REINFORCING MESH

Explore our wide range of products.

Home » Reinforcing Steel Wire

REINFORCING MESH

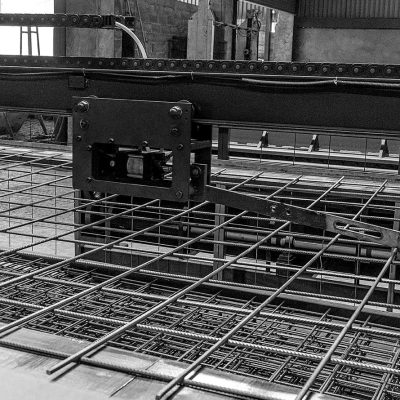

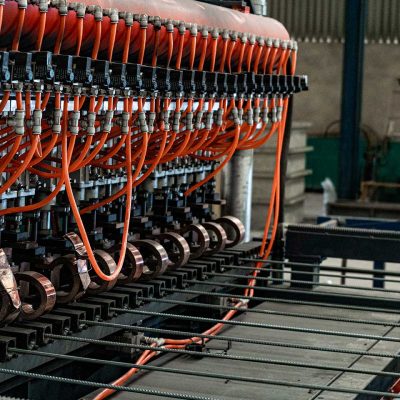

Steellines Zambia brings Welded Mesh Reinforcement (WMR) for the first time in Zambia with state-of-the-art European technology, to eliminate construction waste and save time in the construction of floor, roof concrete slabs and road pavements.

- Available with ribbed wire and deformed bars 3.0mm, 4.0mm, 5.0mm, 6.0mm, 8mm, 10mm, and 12mm.

- Customizable. Any spacing (Box Size) from 50mm to 300mm other sizes and configuration can be produced upon request.

- Wires are Cold Drawn from SAE1010 – able to achieve a minimum of 500mpa Yield Strength.

- No more wasteful and time-consuming. G.I. Wire binding or any other type of slab reinforcement.

Welded Mesh Reinforcement (WMR) sheets are manufactured out of cold-rolled ribbed wires with yield strength of 500 MPa.The longitudinal and transverse wires and bars are electric-resistant welded by applying pressure and passing electric current at the intersection. Welded Mesh Reinforcement (WMR) develops guaranteed shear strength of 240 MPa (35000PSI) at the intersection. This provides a huge anchoring effect in the slab concrete.

The bonding behavior of WWR is significantly enhanced than that of ordinary deformed bars.

As against the peripheral surface area which is responsible for bonding to concrete in the case of individual bars, the rigid mechanical interconnections by means of welds to cross\ wires are primarily responsible for stress transfer from concrete to steel and vice-versa in the case of WWR.

This behavior of positive mechanical anchorage is acknowledged in the specification of much lower lap splice lengths for WWR. This aspect can result in savings of steel vis-à-vis HYSD bars by making easy the option to use a combination of fabrics/ steel areas provided to achieve curtailment of reinforcement with easy and short splices.

The behavior of strong mechanical anchorage of the welds at each of the intersections imparts animmense deal of homogeneity to the R.C.C section as a whole. The two- dimensional uniform stress distribution of the fabric with the concrete achieves better plate behavior in the slab. WWR usage affords the possibility of using thinner wires at closer spacing. This serves most effectively in countering the non-load phenomena or strain- induced stresses due to shrinkage and temperature changes.

The close spacing of thinner wires and the two-way behavior of WWR minimizes the crack widths and preserves the structural integrity of the slab.WWR ensures up to 50% savings in construction labour and time in slab reinforcement work.

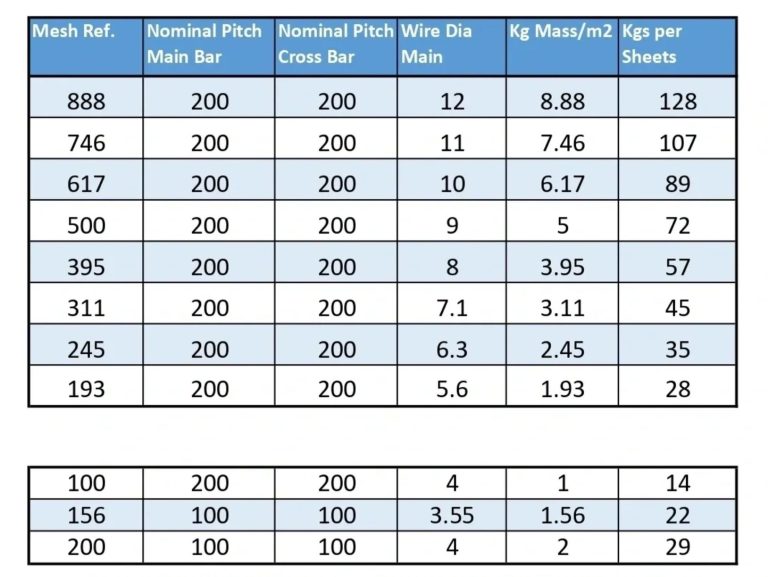

Weld Mesh Reinforcement Chart

If customers can’t find it, it doesn’t exist. Clearly list and describe the services you offer. Also, be sure to showcase a premium service.